F&P Windmill

>>

>>

Renewable energy using Fisher & Paykel Smartdrive Washing machine

2007

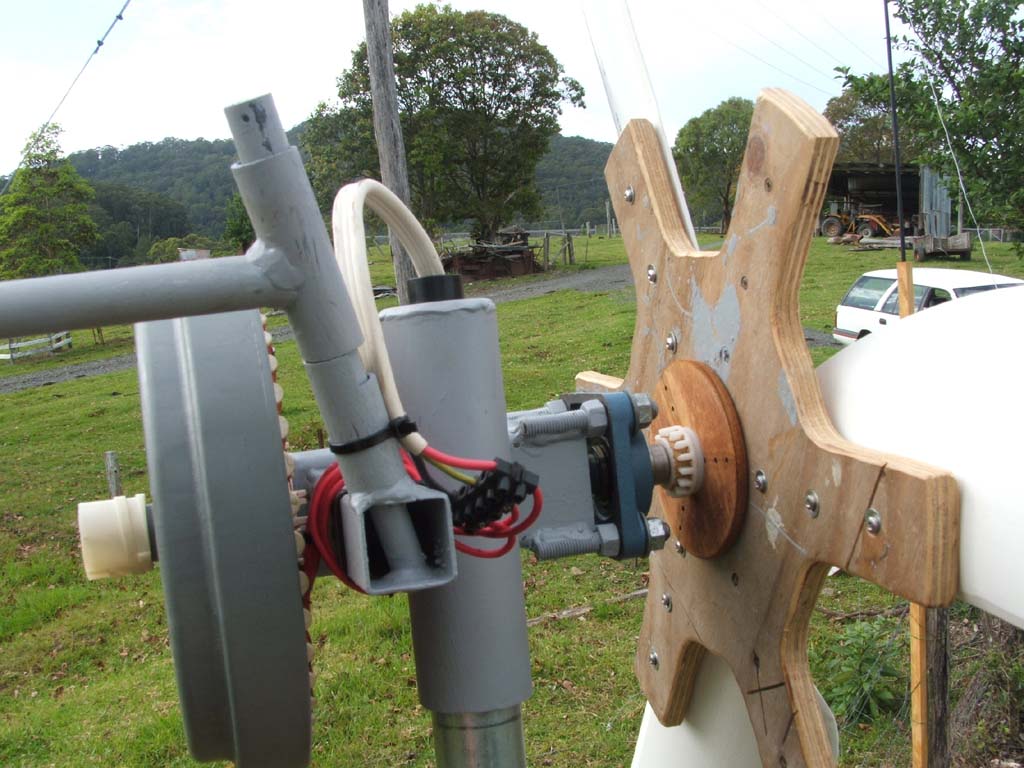

Completed windmill being tested in the weather. Currently 6 months of sun and upto 90kmph winds have not scathed it

The mill spins daily though is not at a high enough height to be efficient. Plans for a 2 x 6 meter towers are in progress. This will clear the trees and produce far more power. The output from the mill is suitable for charging a 12Volt or 24Volt battery pack after rectifying the AC output.

Click any image for a larger version

This shows the PVC blades fastened to a 20mm marine ply holder which mounts to the front of the main windmill shaft. The coils at the back stay stationary. The tail can be seen hanging out the back as well.

Side View

Some blades cut from 250mm PVC pipes. Cutting a set from 300mm PVC would be slightly better though these produce 100W in a decent wind. Having wooden blades would be better and a machine has been created to make these in the future as well.

The blade carver. A 4meter long unit design to copy an existing blade to produce identical units fast which can be cleaned up and finished far easier. Am still trying to get hold of an old blade to use for this purpose.

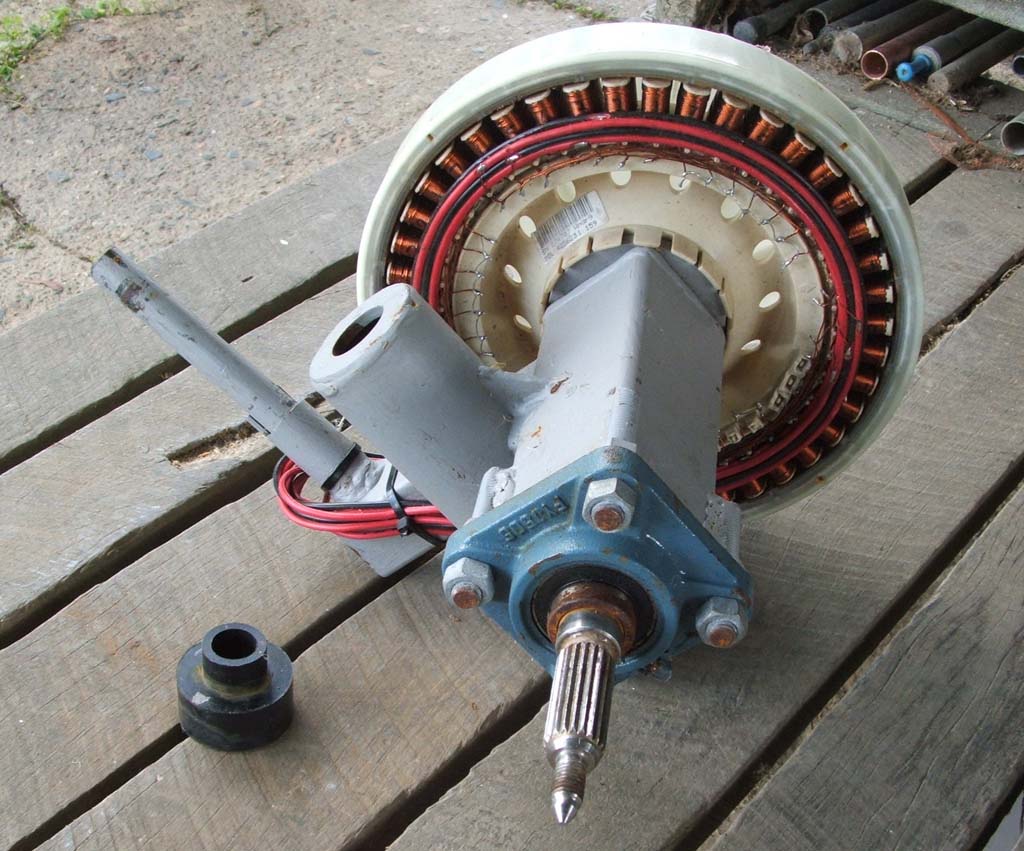

The actual units. Very sturdy welds and 6mm steel, with proper bearings

and rustproof undercoated ready for any colour. The rust on the

stator is purly surface as this unit has been sitting idle.

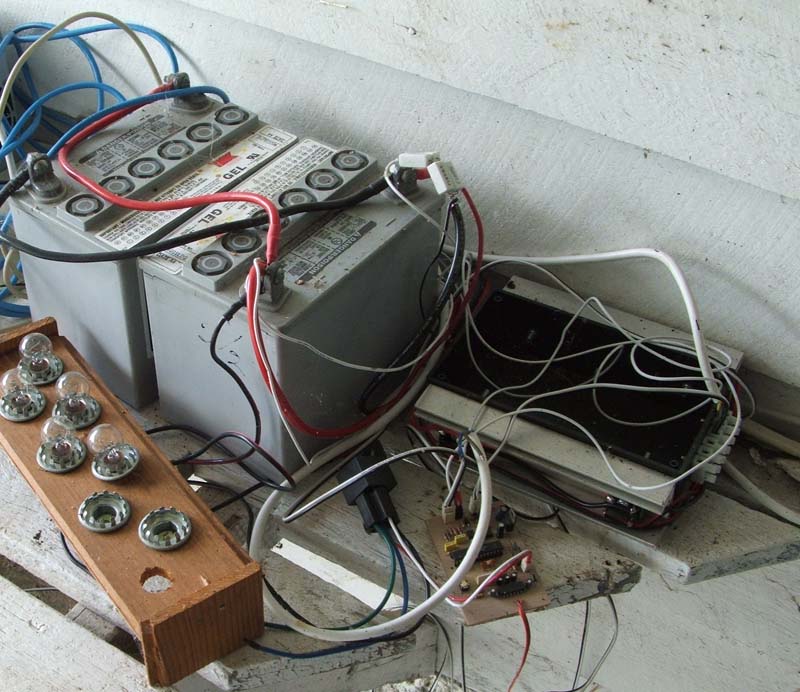

A charging regulator and monitor designed for this unit. It monitors the windmills RPM, output power, windspeed and more.

This currently is sent to a computer to be stored and analysed.

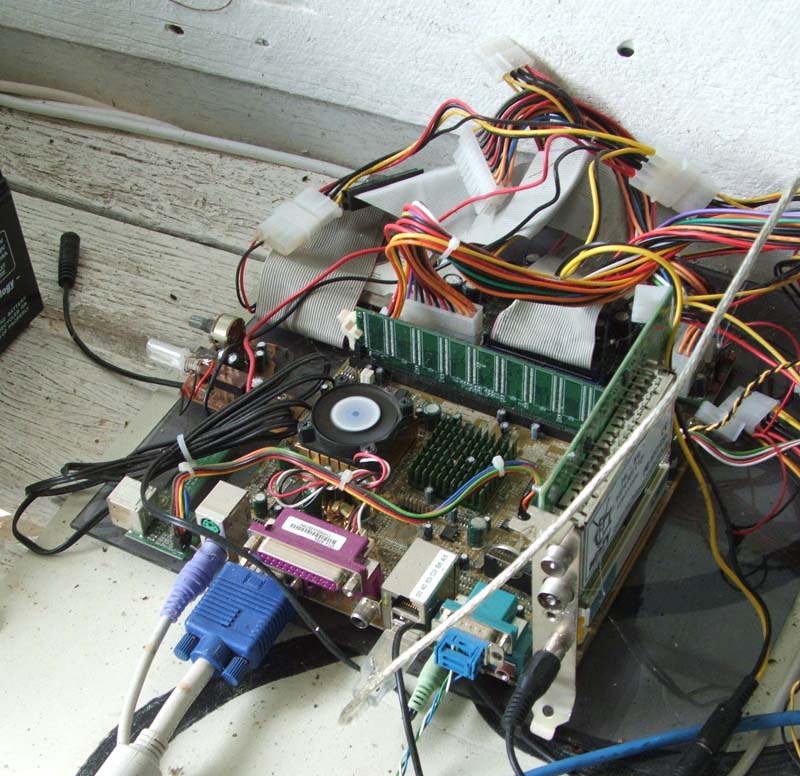

A computer running from the 12V batteries and windmill.

Credits: These units were inspired and created using designs tested and

proven at www.thebackshed.com

For more projects visit http://rifraf.dyndns.org/robotics

For any information Contact rifraf@tpg.com.au

Visit Tiptoes

Hexapod Robot New Website